Vacuum Conveyor type FilterVac - VTS

Working Principle: The FilterVac generates a vacuum (negative pressure) within the receiving container or the machine, ensuring continuous product suction from the storage container or other equipment. The vacuum can be supplied to the Conveyor either by a pump installed on board or the customer’s centralized air system to create the high vacuum values required for this VTS configuration.

During the product aspiration phase, the Vacuum Conveyor regularly cleans the filter and collects residual material in a small container installed at the bottom of its body. At the end of the operation process goes a so-called “purge phase” in which the powder accumulated in this container is recovered either manually or automatically via a closed system using an aspiration hopper.

Customization Options: Design philosophy AGIERRE emphasizes Customer satisfaction. The VTS - FilterVac is available in a fixed version without wheels or can be mounted on a movable structure with antistatic wheels for ATEX applications, allowing easy positioning wherever needed.

The FilterVac can be equipped with an automatic CIP (Cleaning-In-Place) or SIP (Steaming‑In‑Place / Sterilizing‑In‑Place) washing system that improves cleaning efficiency, prevents cross-contamination, and ensures product purity for the production process.

All Vacuum Conveyors, including the FilterVac version, can be further customized to meet specific production process requirements.

Compliance and Safety: The Vacuum Conveyor type FilterVac complies with cGMP and FDA guidelines, UNI EN ISO standards, ATEX and Machinery Directives, and other safety regulations.

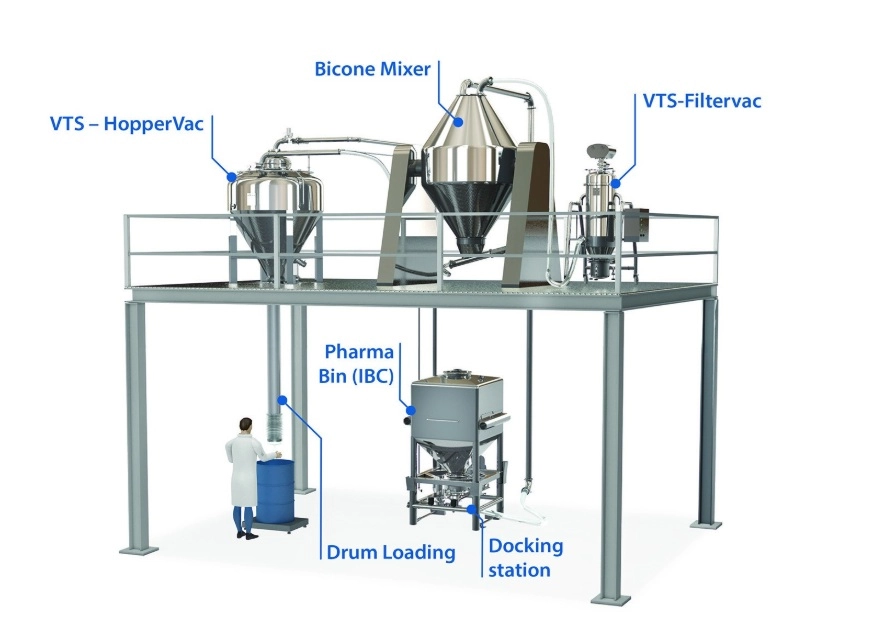

VTS - FilterVac Application for Bicone Mixer Loading from Pharma Bin (IBC

Applications: The image above represents the system for conveying, blending, and dosing powders. The process starts by loading the Bicone from the Bin using a FilterVac Conveyor, which creates negative pressure inside the Bicone. It causes powder suction from one container into another due to the pressure difference.

After the Double Cone Mixer blends the powder, it goes into the HopperVac Conveyor, which plays the role of a Controlled Dosing System for charging material into the Drums. All described operations are carried out through a closed system (Continuous Liner and Docking Station), preserving product integrity and eliminating contamination risks.

Additionally, VTS - FilterVac can be used for loading Mixers, Reactors, and other equipment where a flanged connection for the basic Vacuum Conveyor is unavailable or impractical.