Explosion-Proof Oil-Filled Radiator BYT

GB/T3836.1、GB/T3836.2、GB/T3836.3、GB/T3836.31、IEC60079-0、IEC60079-1、IEC 60079-7、IEC60079-31

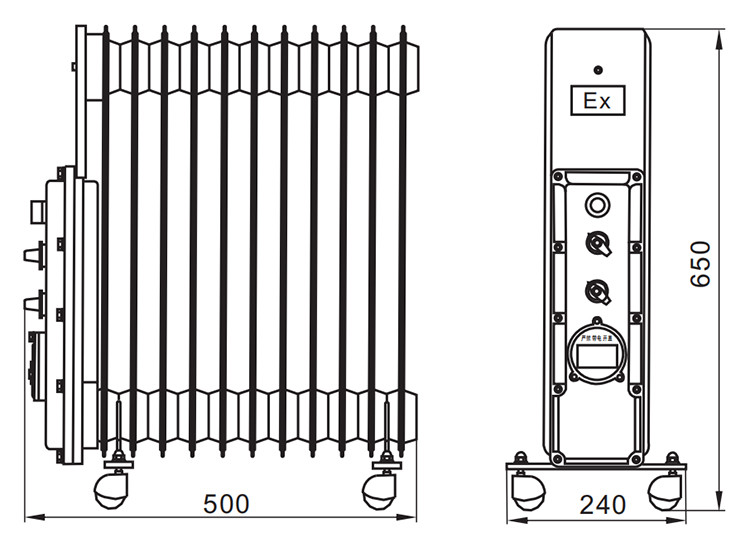

| Model | Rated Voltage (V) | Rated Power (W) | Number of Heat Sinks (Pcs) | Explosion-Proof Marking | Overall Dimensions (mm) | Protection Rating | Corrosion Resistance Rating | Cable Entry Specifications | Applicable Cable Outer Diameter |

|---|---|---|---|---|---|---|---|---|---|

| BYT-1600/9 | AV 220 | 1600 | 9 | Ex db eb IIB T4 Gb | 425×240×650 | IP54 | WF1 WF2* |

G3/4" | φ10~φ14mm |

| BYT-2000/11 | 2000 | 11 | 500×240×650 | ||||||

| BYT-2500/13 | 2500 | 13 | 575×240×650 | ||||||

| BYT-3000/15 | 3000 | 15 | 650×240×650 |

1. Aluminum alloy die-cast housing undergoes high-speed shot blasting followed by high-pressure electrostatic powder coating for corrosion resistance and aging resistance.

2. Stainless steel exposed fasteners provide superior corrosion resistance.

3. The product consists of three components: heating element, explosion-proof junction box/control box, and movable base.

4. The integrated explosion-proof structure combines flameproof and increased safety types.

5. The heating element comprises multiple oil-filled sealed heat sinks with built-in heaters. Heated thermal oil circulates automatically through the piping system, providing stable heat distribution.

6. The explosion-proof junction box and explosion-proof control box form an integrated unit. The junction box features an increased safety explosion-proof structure, with power cables entering via cable glands to connect with terminals. The explosion-proof control box employs a flameproof enclosure design. Its flat flameproof surfaces are bolted to the heating element to form an integrated assembly. Internal electrical components include a power regulator, temperature controller, and power indicator light. Grounding devices are installed both inside and outside the junction box.

7. The mobile base consists of a support frame and swivel casters, mechanically fixed to the oil radiator to form an integrated unit. This allows the radiator to move freely and change direction on relatively smooth floors or surfaces.

8. Cable routing.

1. Suitable for Zone 1 and Zone 2 locations in explosive gas environments;

2. Suitable for Class IIA and IIB explosive gas environments;

3. Suitable for temperature classes T1 to T4;

4. Suitable for use in production workshops, control rooms, analytical laboratories, gas stations, warehouses, caves, and similar locations for winter heating and indoor temperature control.