Explosion-Proof Axial Flow Fan BAF

GB/T3836.1、GB/T3836.2、GB/T3836.31、IEC60079-0、IEC 60079-1、IEC 60079-31

| Explosion-Proof Marking | Protection Rating | Cable Outer Diameter | Entry Thread |

|---|---|---|---|

| Ex db IIB T4 Gb Ex db IIC T4 Gb Ex tb IIC T135°C Db |

IP54 | φ10-φ14 | M26*1.5 perhaps G3/4" |

| Specifications | Impeller Diameter (mm) | Motor Power (kW) | Rated Voltage (V) | Rated Speed (r/min) | Airflow (m³/h) | Default Air Outlet Direction | Corrosion Resistance Rating | |

| Three-phase | Single-phase | |||||||

| BAF-200 | 200 | 0.09 | 380 | 220 | 2800 | 1230 | Front end of the impeller | WF1、WF2* |

| 0.06 | 1450 | 618 | ||||||

| BAF-300 | 300 | 0.18 | 1440 | |||||

| BAF-400 | 400 | 0.25 | 2800 | |||||

| BAF-500 | 500 | 0.37 | / | 5700 | ||||

| BAF-600 | 600 | 0.55 | 8700 | |||||

1. This series of ventilators is designed based on the three-dimensional flow theory of impeller mechanics, with meticulously engineered test data to ensure excellent aerodynamic performance. They feature low noise, high efficiency, minimal vibration, and low energy consumption.

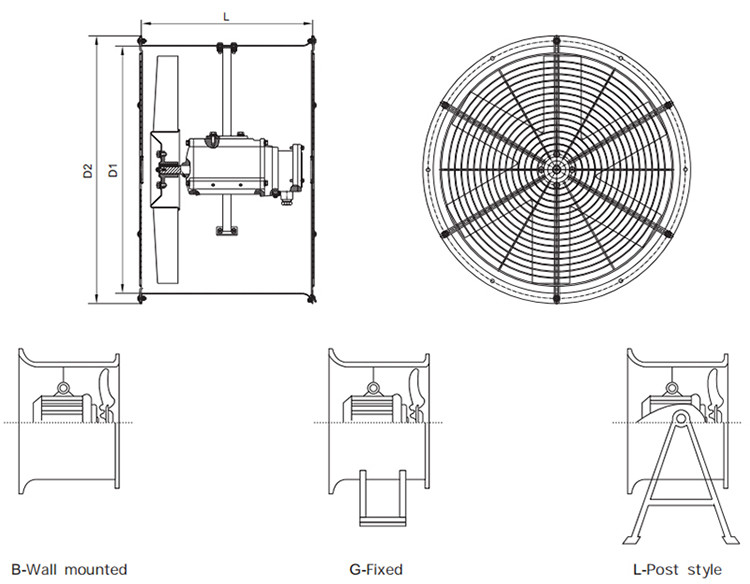

2. The ventilator consists of an explosion-proof motor, impeller, air duct, protective cover, and louvers.

3. Steel pipe or cable wiring.

| Machine Number | L (mm) | D1 (mm) | D2 (mm) |

|---|---|---|---|

| 200 | 310 | 210 | 250 |

| 300 | 310 | 355 | |

| 400 | 330 | 410 | 465 |

| 500 | 510 | 565 | |

| 600 | 610 | 665 |

1. Suitable for Zone 1 and Zone 2 locations in explosive gas environments;

2. Suitable for Class IIA, IIB, and IIC explosive gas environments;

3. Suitable for Zone 21 and Zone 22 locations in explosive dust environments;

4. Suitable for Class IIIA, IIIB, and IIC explosive dust environments;

5. Suitable for temperature classes T1 to T4;

6. Widely used in hazardous environments such as oil refining, chemical processing, textiles, and military industries, as well as offshore oil platforms and oil tankers;

7. Indoor and outdoor use.